Tidewall vinyl sheet pilings are engineered for installation into the ground, similar to the process used for driving steel sheet piles. Various techniques and equipment are employed for this purpose. Discover how to install your vinyl sheet pilings with these several common sheet piling driving methods and options.

Vibro Hammer

This process involves utilizing a vibro hammer to simultaneously raise the sheets and securely embed them into the ground by vibration. It's important to note that for vinyl pilings, lighter vibro hammers are recommended compared to those typically employed for steel piling.

Plate Compactor

For regions with soil of moderate stiffness or lower, vinyl sheet pilings can be effectively driven into the ground using a plate compactor attached to a backhoe, ensuring a smooth and efficient installation.

Compression Driving

In regions with highly soft soils, a straightforward compression driving technique proves effective for vinyl sheet pilings installation. This method involves using the backhoe's bucket to apply vertical force onto the sheets, ensuring a smooth insertion into the ground. Notably, this approach is particularly suitable for the heavier vinyl sheet pilings, such as those with a TW85 rating and higher.

Pile Driver

Vinyl Sheet Piling Info & Specs

When installing vinyl sheet pilings in sandy terrain, jetting serves as an effective installation technique. This method involves utilizing a pump to elevate and increase the speed of a water stream, directed through a wand to the base of the sheets. The force of the water displaces the sand, enabling the Tidewall to be gently positioned. Once the water jet is discontinued, the displaced sand naturally resettles around the sheets.

Jetting

When installing vinyl sheet pilings in sandy terrain, jetting serves as an effective installation technique. This method involves utilizing a pump to elevate and increase the speed of a water stream, directed through a wand to the base of the sheets. The force of the water displaces the sand, enabling the Tidewall to be gently positioned. Once the water jet is discontinued, the displaced sand naturally resettles around the sheets.

60-Year Warranty

UV-resistant, window-grade PVC mean your vinyl sheet pilings will stand the test of time -- in the constant blazing sun, through battering storms, and never-ending wave action. That's why your Tidewall vinyl sheet pilings come with a 60-year warranty. Let your great-grandkids worry about replacing the bulkhead.

Excellent Prices, Design Assistance, Timely Delivery

You can count on excellent prices from American Pole & Timber — usually the lowest vinyl sheet piling prices you will find. The knowledgeable project consultants at American Pole & Timber will help you select the best profile for your project and choose the best hardware and wood components.

Your delivery will be timely and accurate. All orders are checked and re-checked before shipping and we have multiple delivery options including special on site forklifts to make unloading simple for you and your crews.

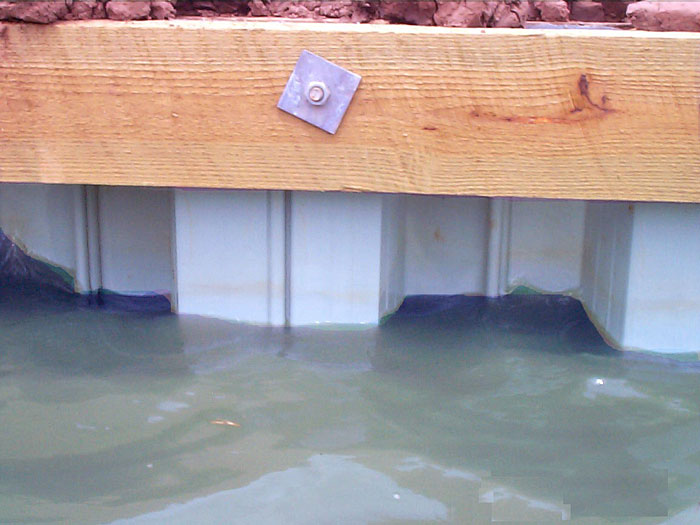

Commercial and Industrial Composite Bulkhead and Retaining Walls

Our Project Consultants can help you optimize your seawall or bulkhead structure for free. We can prepare and ship your retaining wall or bulkhead so you will be ready to build when it arrives.

Contact Us

Technical Papers